Overview

As the global demand for renewable energy continues to rise, wind power generation stands out as a key contributor to sustainable electricity production. However, maintaining the optimal performance and longevity of wind turbines remains a challenge for operators. Vibration analysis plays a crucial role in identifying potential issues and optimizing turbine efficiency. In this case study, we explore how a solution provider utilizes FFT (Fast Fourier Transform) algorithm-based vibration analysis to enhance the operations of a wind power generation company.

Client Background

Our client, a global renewable energy generation company both onshore and offshore, operates a sizable portfolio of wind farms across diverse geographical locations. They aim to maximize energy output while ensuring the reliability and safety of their turbines in India. However, they faced challenges related to equipment downtime, maintenance costs, and performance optimization.

Challenges

The new technology adoption may create several challenges while adopting within businesses. These challenges may includes:

- Equipment Downtime: Unplanned downtime due to turbine failures or maintenance activities impacts revenue generation.

- Maintenance Costs: Reactive maintenance practices lead to higher costs and disrupt operational efficiency.

- Performance Optimization: Inefficient operation of turbines results in suboptimal energy production and reduced profitability.

- Predictive Maintenance: Lack of predictive maintenance strategies hampers the ability to address issues before they escalate.

Solution

- Vibration Monitoring System Installation:

- Deploying high-quality vibration sensors strategically on key components of the wind turbine, such as the gearbox, bearings, and blades.

- Integration with a centralized monitoring system for real-time data collection and analysis.

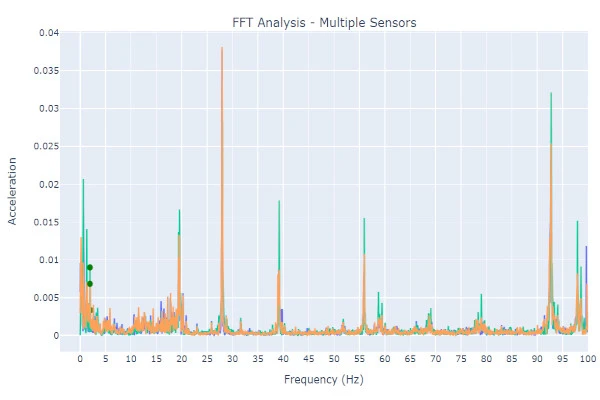

- FFT Algorithm-based Analysis:

- Utilizing FFT algorithm to convert time-domain vibration signals into frequency-domain spectra.

- Identifying frequency components associated with specific faults or anomalies, such as bearing defects, imbalance, misalignment, and blade damage.

- Anomaly Detection and Predictive Maintenance:

- Developing machine learning algorithms to analyze vibration data patterns and detect early signs of equipment degradation or impending failures.

- Implementing predictive maintenance strategies to schedule maintenance activities proactively, minimizing downtime and reducing maintenance costs.

- Performance Optimization:

- Analyzing vibration data to identify opportunities for optimizing turbine operation parameters, such as rotor speed and pitch angle adjustments.

- Providing actionable insights to improve energy capture efficiency and overall turbine performance.

Results Achieved

- Reduced Downtime: Early detection of potential failures and proactive maintenance interventions led to a significant reduction in unplanned downtime.

- Cost Savings: Transitioning from reactive to predictive maintenance practices resulted in substantial cost savings associated with maintenance activities and equipment repairs.

- Improved Performance: Optimization of turbine operation parameters based on vibration analysis insights led to enhanced energy production and increased profitability.

- Enhanced Reliability: The implementation of a comprehensive vibration monitoring and analysis system improved the overall reliability and safety of the wind turbines.

Conclusion

By leveraging vibration analysis techniques, particularly FFT algorithm-based analysis, our solution empowered the wind power generation company to overcome operational challenges, enhance performance, and maximize profitability. The proactive approach to maintenance and optimization underscored the value of advanced analytics in the renewable energy sector, demonstrating the transformative impact of technology-driven solutions in ensuring sustainable energy production.

Testimonial

Their expertise has streamlined our data management by efficiently preprocessing data at the file level and streaming it to the FFT algorithm. This process has significantly reduced the volume of data pushed into our database. Moreover, their ability to extract peak values and store them for wind farm-level analysis has greatly enhanced our decision-making capabilities. We're truly impressed with the results achieved.

Senthil Mani

Gamesa Renewable Private Limited